All images copyright Sustainable Design Consulting, LLC

Earlier this month, SDC’s Kara Strong and Brendan Collier presented ‘Designing for Low-Carbon Buildings’ at DesignDC. Miss it? They’ve now distilled it down to this summary on using life-cycle assessments (LCAs) . . .

. . . to reduce embodied carbon

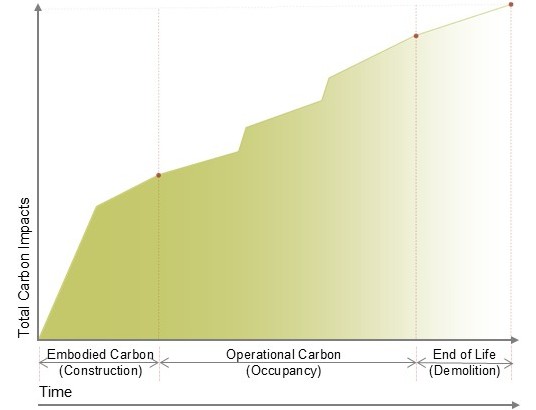

As buildings become more energy-efficient, embodied carbon plays an increasingly significant role in how buildings contribute to climate change. Embodied carbon refers to greenhouse gases associated with the production and use of building materials. By 2030, experts project that embodied carbon will be responsible for the majority of the carbon emissions associated with global new building and infrastructure.

Re-using existing buildings is the best strategy for reducing the embodied carbon inherent in construction. When new construction is necessary, LCAs allow design teams to determine the potential environmental impacts of the materials used in building construction.

LCAs begin by identifying the quantity of each material used in the project. For each material, its total quantity or weight is multiplied by its environmental impacts. The sum of these impacts determines the building’s overall LCA. While LCAs include the impacts across multiple categories of concern, most project teams focus on global warming potential (GWP), also known as embodied carbon.

. . . to reduce the embodied carbon of structural materials

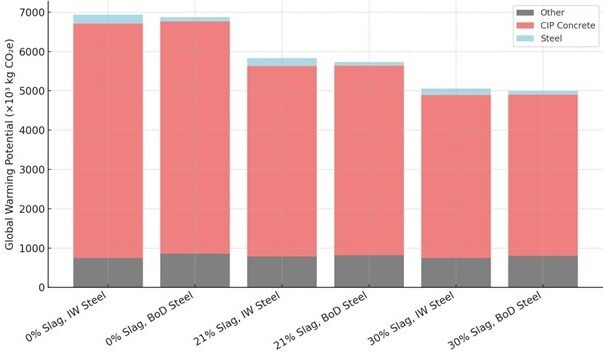

LCAs demonstrate that the structural system is responsible for the greatest environmental impact, as they represent the greatest quantity (by mass) of materials in the project. Therefore, to significantly reduce the embodied carbon in new construction, teams should focus on low-carbon structural systems. When specifying steel, concrete, or wood, focus on construction processes with the lowest carbon impacts.

In the Washington, DC area, concrete is the greatest single contributor to the embodied carbon of buildings. Clinker, the main component of cement, is produced by heating limestone at high temperatures and produces large amounts of CO₂ per ton. Supplementary cementitious materials (SCMs) are added to concrete to partially replace Portland cement in ready-mix concrete, enhancing its properties and reducing its carbon footprint. Common SCMs include Type 1L, or raw limestone, fly ash, a waste byproduct of coal power plans, blast furnace slag, a waste byproduct of steelmaking, and ground glass pozzolan, created from recycled glass.

. . . as a design tool

To reduce the embodied carbon of building materials beyond selecting ‘better’ materials, LCAs can be used to study the potential environmental benefits of design and structural decisions. The earlier the studies, the more opportunities to greatly reduce the embodied carbon of the project. When new construction is necessary, architects should coordinate with the owner to reduce the size of the project as much as possible: by looking for redundancies in the program, including multi-functional spaces, etc.

After reducing the new construction requirements, structural engineers are key for further embodied carbon reductions. They can both develop structural systems that incorporate alternative building materials and can also consider systems that reduce the overall amount of material needed, often by strengthening design components. In both cases, LCAs will confirm which strategy will provide the project with the lowest carbon footprint.